A Legacy of Quality

Discover how technological solutions created by Federal-Mogul Powertrain maintain the optimal heartbeat of an engine.

For over a century, Federal-Mogul Powertrain has been developing and delivering innovative technologies that meet specific customer, regulatory and market requirements.

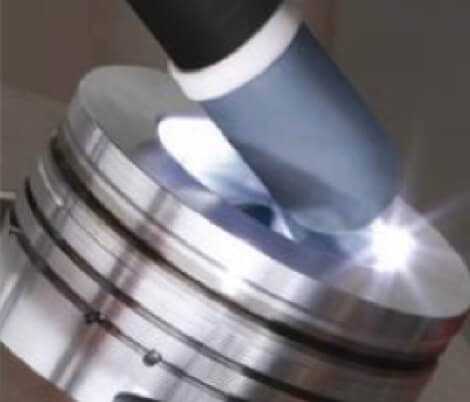

At Federal-Mogul Powertrain, we pride ourselves on our advanced technological solutions, facilitating fuel efficiency and emissions reduction and extending the engine service life. The company’s advanced component designs, specialized coatings and proprietary manufacturing processes ensure friction reduction, supporting engine downsizing, higher compressions rations and improved performance.

Federal-Mogul designs and produces an extensive portfolio of engine components for the smallest engines with 25mm bore size up to the world’s largest engines with 980mm bores and 1000,00hp. Our precision technologies achieve single-digit tolerances and are engineered to withstand the toughest conditions in today’s highly loaded engines.